RITEOHMS" BRAND WIRE WOUND RESISTOR -

ALUMINUM HOUSED AXIAL LUG LEAD - Professional Grade

Features:

- High Power to size ratio

- Low surface temperature

- Elegant look over whole range.

- Exceptional stability and reliability against severity of damp heat conditions and other environmental abuses.

- Low temperature coefficient over entire range

- Anodized aluminum housing ensures good humidity seal

- Designed with serrations on Aluminum housing for proper thermal conductivity

- Terminations are silver plated

- High level voltage protection

- Non-standard ohmic values available.

Non inductive and special terminations available

General Specifications:

Test |

Conditions |

Tolerances |

± 1%, ± 2%, ± 5%. |

Power Ratings |

5 watts to 500watt |

Resistance Series |

E24 Series |

Resistance Range |

0.05 E - 100 KE |

Resistant Element |

Copper-nickel alloy, or nickel chrome alloy |

Housing |

Anodized Aluminum |

Core Material |

Ceramic steatite |

Temperature Range |

-55C to 250C |

Insulation Resistance |

Min. 10 G ohms |

Dielectric Strength |

AC; Max. leakage current : 2mA

1500VAC peak ;

2500VAC (Optional)

5000VAC (Optional) |

Short Time Overload |

2 X wattage rating - 5sec |

Load Life |

Wattage rating 1.5h. ON, 30min. OFF, 1000 hours |

Thermal Shock |

wattage rating 30min., -55 C, 15-30minutes |

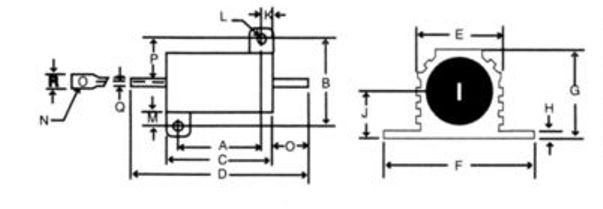

Mechanical Data:

POWER (Watt) |

A |

B |

C |

D |

E |

F |

G |

H |

L |

10 |

14.3 |

15.9 |

19 |

35 |

11 |

21 |

10 |

2 |

2.4 |

25 |

18.3 |

19.8 |

27 |

50 |

14 |

27.5 |

14 |

2.25 |

3.18 |

50 |

39.8 |

21.4 |

50 |

72 |

16 |

29 |

15.5 |

2.25 |

3.18 |

75 |

29 |

37 |

49 |

71 |

27 |

48 |

26 |

3.5 |

4.4 |

100 |

35 |

37 |

65.5 |

83 |

27 |

48 |

26 |

3.5 |

4.4 |

150 |

70 |

57 |

89 |

139 |

46 |

72 |

45 |

5 |

5 |

250 |

98.5 |

63.5 |

115 |

178 |

54 |

76 |

56 |

6.5 |

5 |

500 |

180 |

63.5 |

200 |

263 |

54 |

76 |

56 |

6.5 |

5 |

Dimensions unless specified in mm

Standard terminations:

- 10-100 watt soldered terminations

- 150-500 watt threaded terminations

Construction

RITEOHMS: These resistors consist of a resistance element wounded on the special grade ceramic rod and embedded into an aluminum case. The wire used is of low temperature co-efficient. The wire ends are spot welded to the end caps. This gives reliable contacts over long period of use. The aluminum casing made from high quality heat sink grade helps to dissipate the heat from the resistor at the faster rate and has a low change of resistance with respect to temperature, with resistance varying in direct proportion. This type of wire wound resistor is manufactured such that the aluminum enclosure is filled with special non-flammable silicon base cement paste.

Electrical Characteristics

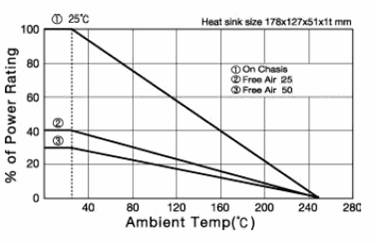

DERATING

The power that the resistor can dissipate depends on the operating temperature

- RITEOHMS resistors have an operating temperature range of: -55C to 250C.

- Derating is required for reduced chassis mounting area and for high ambient temperatures.

- The following curves apply to operation of un mounted resistor

- Heat sink size: 178X127X51X1t mm

Test and Requirements

TEST ITEM |

CHARACTERISTICS |

Resistance tolerance |

Tolerance resistance ±10%(K) |

Temperature coefficient |

±200PPM/°C MAX |

Power rating load |

Δ R/R ≤ ±(0.5% + 0.1W)

Surface temperature up 350°CMAX |

Short-term overload |

Free of appearance or structural irregularity

Δ R/R ≤ ±(2% + 0.1W) |

Insulation resistance |

100MW min |

Dielectric withstanding voltage |

Free of appearance or structural irregularity

Δ R/R ≤ ±(0.1% + 0.05W) |

Terminal strength |

Free of appearance or structural irregularity |

Resistor strength |

Free of appearance or structural irregularity |

Vibration |

Free of appearance or structural irregularity

Δ R/R ≤ ± (1% + 0.05Ω) |

Thermal shock |

Resistor free of structural irregularity

Crack of silicon cement surface

Δ R/R ≤ ± (2% + 0.1Ω) |

Humidity |

Free of appearance or structural irregularity

Δ R/R ≤ ± (3% + 0.1Ω) |

Load life |

Free of appearance or structural irregularity

Discoloration of marking

Δ R/R ≤ ± (3% + 0.1Ω) |