Technical Specification for Wire Wound Rheostats, Hand sliding Tupe

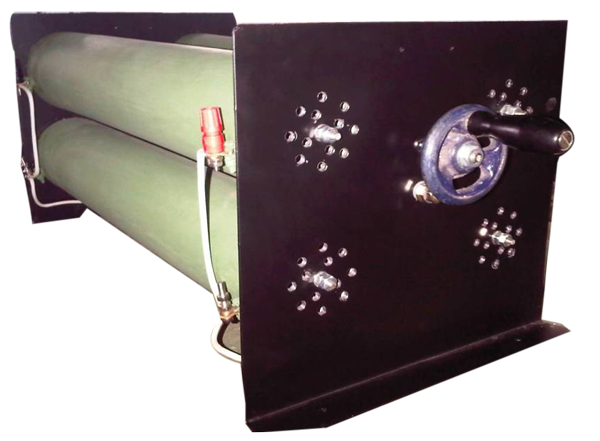

1) Core porcelain tube, non magnetic, non inductive tobular type

2) Contact block: square piece made of brass material is fitted with contact sliders in the guide rod. Bright chrome plated phosphors bronze strip which makes immediate contact with the guide rod. A backlit knob is fitted with square piece for sliding up and down

3) Solid draven brass rod bright chrome plated square

4) Contact Material: Multiple brushes of phosphorus bronze strip, rolled strip gives springy action to contacts

5) Winding Wires : Eureka wire for low ohmic value and nichrome wire 80/20 grade for high values

6) Temprature rise – 200 degree C above ambient temperature

7) High Voltage Test : 2KV AC for 1 minute between end support and any one of 3 wires terminal of the wire

8) End support – Aluminium bracket plated

9) Terminals: Bright chrome plated bass nuts and screws one at each end of leaner type wire wound resistors and third one at both the side of the guide rod

10) All electrical connectors are made from chrome plated material

11) Rotary Sliding rheostats, double tbe and multiple tubes Non standard value wattage on specififc request Available from 100M A to 100 A 0.3 ohms to 25KE